Just how to Select the Right Light Weight Aluminum Shop for Your Production Demands

Selecting the ideal aluminum foundry is crucial for successful production end results. Factors such as project specs, shop capabilities, and interaction techniques play considerable duties in this decision-making procedure. Comprehending the nuances of each element can considerably affect the effectiveness and high quality of the end product. As the intricacies of these considerations unfold, it is crucial to explore what genuinely defines an ideal partnership in aluminum shop selection.

Recognizing Your Manufacturing Requirements

When selecting an aluminum foundry, understanding production requirements is essential, as it directly influences the top quality and effectiveness of the end products. Each project has special specs, including dimensions, resistances, and product buildings that must be plainly specified. The desired application of the aluminum components additionally plays a crucial function; whether they are for aerospace, auto, or consumer items, the demands can vary substantially.

Furthermore, factors such as manufacturing volume, target dates, and budget restrictions must be taken into consideration. For instance, high-volume production may require different strategies or devices than low-volume personalized orders. Understanding these parameters permits much better communication with the shop, guaranteeing that capacities line up with expectations. Ultimately, an extensive grasp of manufacturing requirements brings about educated choices, reducing the danger of top quality issues and improving total job success. This foundational step sets the phase for a productive collaboration with the chosen light weight aluminum factory.

Reviewing Factory Capabilities and Experience

To guarantee an effective partnership with a light weight aluminum foundry, assessing its abilities and experience is vital - Aluminum Foundry. Potential clients should begin by examining the factory's manufacturing procedures, consisting of spreading approaches, alloy choice, and ending up methods. Recognizing these capabilities assurances that the foundry can fulfill specific production demands

Experience is similarly important; a reputable foundry usually has a wide range of knowledge regarding market criteria and quality control actions. Examining instance studies or testimonies can offer insight right into the factory's previous projects and consumer satisfaction levels. Additionally, it is helpful to ask regarding the shop's labor force experience and any type of qualifications held, as these aspects contribute to total integrity and capability.

Analyzing Technological Innovations

When selecting a light weight aluminum foundry, evaluating technological developments is vital for ensuring top quality end results. Cutting-edge casting techniques, in addition to enhanced automation and performance, can considerably influence manufacturing timelines and expenses. Additionally, durable quality control steps are essential for keeping the stability of the final products.

Innovative Casting Methods

Advancements in casting modern technologies are reshaping the aluminum factory landscape, allowing producers to achieve better accuracy and efficiency. Methods such as die spreading, lost foam spreading, and financial investment spreading are obtaining grip, enabling complex layouts and decreased material waste. Additionally, using computer-aided style (CAD) and simulation software improves the casting process by enhancing and anticipating prospective flaws mold design. These innovative approaches not only enhance item high quality yet also reduce lead times, making manufacturing much more dexterous. Furthermore, innovations in alloy solutions add to lighter yet more powerful elements, providing to industry needs for performance and sustainability. As light weight aluminum factories adopt these strategies, they position themselves to fulfill developing market needs successfully.

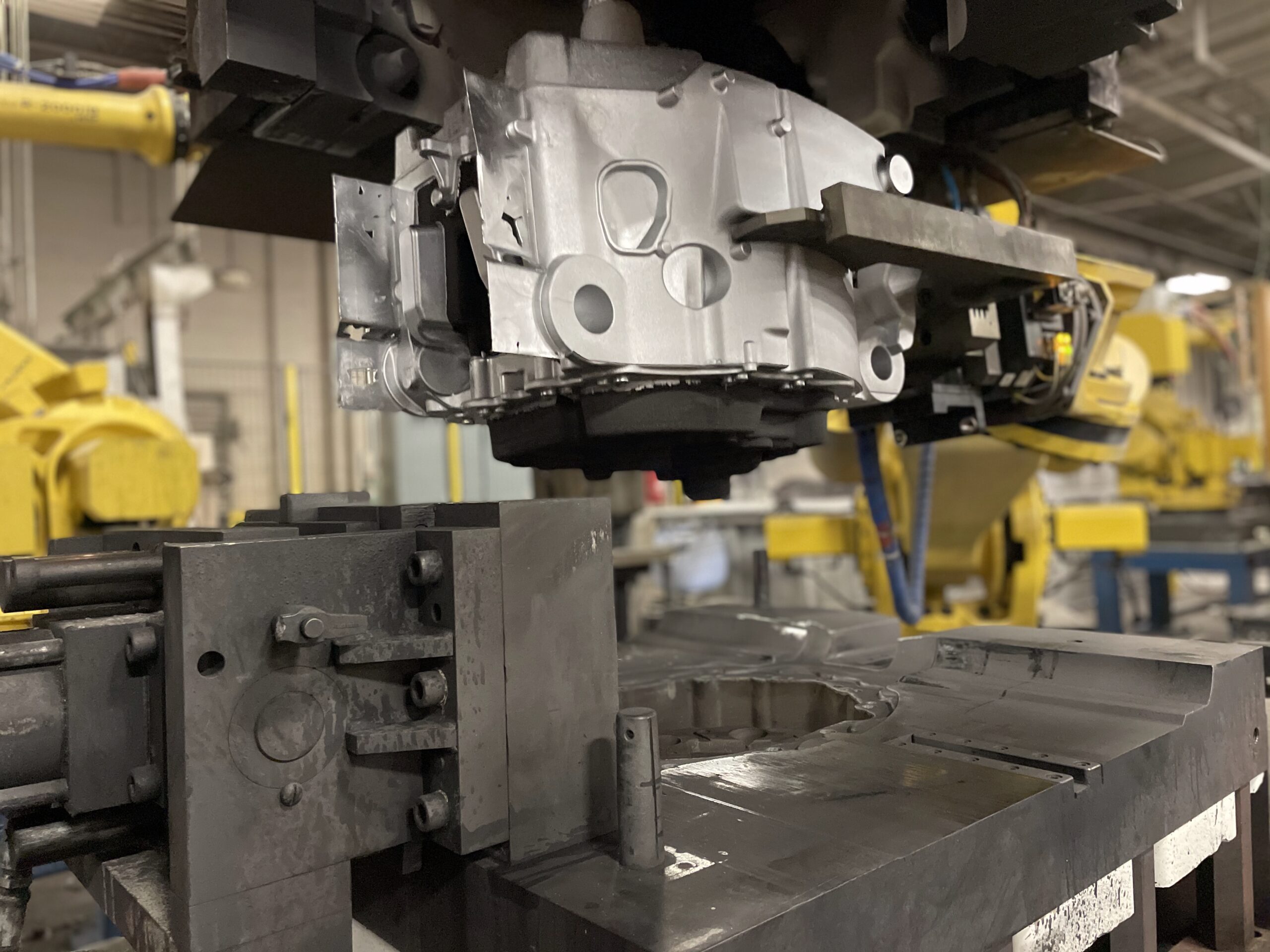

Automation and Effectiveness

As aluminum foundries progressively accept automation, they significantly boost functional performance and efficiency. Advanced robotic systems and automated equipment enhance the casting procedure, decreasing labor prices and reducing human error. These technical innovations make it possible for regular manufacturing rates and allow for better flexibility in producing different aluminum parts. Additionally, automation assists in real-time tracking of production criteria, bring about enhanced operations and resource management. Foundries that embrace automated solutions can swiftly adjust to adjustments in demand, making sure timely distribution of items while preserving high output degrees. By buying automation, aluminum foundries place themselves competitively on the market, satisfying the expanding needs for effectiveness and precision in manufacturing. Eventually, this change towards automation represents a substantial advance in the industry.

Quality Control Measures

Quality guarantee stays a crucial element of the aluminum foundry industry, particularly as technical developments remain to improve manufacturing processes. Modern shops are progressively taking on advanced top quality control procedures, such as real-time tracking systems and progressed data analytics. These innovations enable exact tracking of product homes and production specifications, making certain consistent product high quality.

Furthermore, automatic assessment methods, consisting of laser scanning and X-ray analysis, enable the discovery of defects that may or else go unnoticed. Carrying out these procedures not just improves item dependability but also lowers waste and revamp. Consequently, factories that prioritize high quality control can enhance client satisfaction and maintain an one-upmanship. Evaluating a shop's dedication to quality guarantee is vital for making sure perfect production end results.

Relevance of Quality Assurance Processes

Quality assurance processes are important in aluminum factories as they ensure the stability and reliability of the end products. Efficient assessment and screening methods, adherence to qualification requirements, and robust traceability and documents practices add to maintaining premium quality. These elements jointly improve customer trust fund and satisfaction in the factory's output.

Assessment and Screening Approaches

While picking a light weight aluminum factory, recognizing the inspection and testing approaches used is vital for making sure the integrity of the final item. A credible shop will apply a range of high quality control procedures, consisting of aesthetic inspections, dimensional checks, and non-destructive testing techniques such as ultrasonic or X-ray exams. These methods are essential for determining any issues or disparities within the castings. Additionally, the shop should follow organized testing protocols to evaluate mechanical residential properties like tensile stamina and find more information solidity. Normal surveillance and documents of these processes provide transparency and guarantee to customers relating to the high quality of the aluminum components produced. Inevitably, a factory's commitment to strenuous evaluation and testing signifies its commitment to providing high-quality items that fulfill sector requirements.

Certification Requirements Compliance

Exactly how can compliance with qualification requirements enhance the integrity of a light weight aluminum shop? Sticking to well-known qualification criteria guarantees that a shop implements extensive quality assurance processes. These criteria commonly incorporate numerous aspects, consisting of product specifications, manufacturing approaches, and environmental considerations. By read review accomplishing accreditation, a shop shows its commitment to preserving top quality output and functional excellence. This compliance not only promotes consumer depend on yet also minimizes the threat of defects and rework, therefore enhancing total effectiveness. Furthermore, accredited shops are more probable to remain upgraded with market innovations, ensuring they make use of best techniques and innovations. Eventually, accreditation standards function as a criteria for quality control, making them crucial for any aluminum foundry aiming for lasting success in the marketplace.

Traceability and Documentation

Traceability and documents are important parts of reliable quality assurance procedures in an aluminum shop. These techniques guarantee that every stage of production is tape-recorded, permitting the tracking of materials, procedures, and final items. This systematic technique aids in determining any type of defects or incongruities that might arise, promoting timely restorative actions. Furthermore, comprehensive paperwork supplies a historic document that can be indispensable for audits and compliance with sector standards. It additionally cultivates transparency between the foundry and its clients, building depend on and confidence. Eventually, a foundry that focuses on traceability and documentation is much better outfitted to preserve high-grade criteria, lower waste, and improve total operational efficiency, guaranteeing that consumer requirements are regularly fulfilled.

Client Service and Communication

When choosing a light weight aluminum foundry, evaluating client service and interaction can significantly influence the total experience. A foundry that prioritizes reliable communication promotes a joint relationship, ensuring that task specifications are clearly comprehended and satisfied. Responsiveness to inquiries and problems is necessary; quick replies can show a committed team that values consumer complete satisfaction.

Clear interaction concerning job progress, obstacles, and timelines assists to develop trust. It's vital for possible clients to gauge how well the foundry pays attention and adapts to specific demands, which can improve the manufacturing process.

In addition, customer care need to prolong past initial communications; click reference long-term assistance can be indicative of a factory's dedication to quality. A firm that uses comprehensive after-sales solution is often much better furnished to deal with future jobs and adjustments. Eventually, strong client service and communication can result in a much more efficient and enjoyable collaboration in between the client and the shop.

Rates and Preparation Considerations

Lead time is influenced by the foundry's manufacturing ability, present workload, and the schedule of resources - Aluminum Casting. A foundry with advanced machinery and appropriate staffing might give quicker turn-around times, while a backlog of orders can prolong preparations substantially. Interaction about particular job timelines and demands is crucial for aligning expectations. Inevitably, selecting a foundry includes stabilizing price with the urgency of production requires to ensure timely delivery without jeopardizing high quality

Often Asked Inquiries

What Sorts Of Aluminum Alloys Can the Shop Collaborate With?

The shop can collaborate with numerous light weight aluminum alloys, consisting of 1000 series (pure light weight aluminum), 2000 collection (copper alloys), 3000 collection (manganese alloys), 4000 series (silicon alloys), 5000 collection (magnesium alloys), and 6000 collection (magnesium-silicon alloys)

Can the Foundry Take Care Of Custom Alterations or layouts?

The factory's ability to deal with customized designs or alterations greatly varies. Prospective clients need to ask about the foundry's modern technology, experience, and adaptability to guarantee it meets their details layout and production requirements successfully.

What Is the Factory's Minimum Order Quantity?

The factory's minimum order quantity differs based upon production capabilities and material prices. Potential customers ought to inquire directly to ascertain certain requirements, making certain the order lines up with both financial constraints and manufacturing timelines.

What Certifications Does the Factory Hold for Quality Criteria?

The factory holds several qualifications, including ISO 9001 for high quality management, ISO 14001 for environmental monitoring, and possibly AS9100 for aerospace applications, guaranteeing adherence to rigorous quality requirements in its manufacturing processes.

Exactly how Does the Shop Ensure Environmental Sustainability in Its Processes?

The foundry applies various strategies for ecological sustainability, consisting of recycling scrap aluminum, using energy-efficient modern technologies, reducing waste discharges, and adhering to stringent ecological laws, thus lessening its eco-friendly impact throughout the manufacturing procedure.

Selecting the appropriate aluminum factory is important for effective production outcomes. When selecting a light weight aluminum shop, understanding production requirements is crucial, as it directly influences the high quality and performance of the last items. By investing in automation, light weight aluminum shops position themselves competitively in the market, meeting the growing needs for efficiency and precision in production. Quality assurance stays a vital aspect of the aluminum foundry market, specifically as technological developments proceed to improve manufacturing procedures. Quality control procedures are important in aluminum shops as they guarantee the honesty and integrity of the last products.